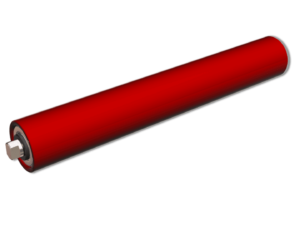

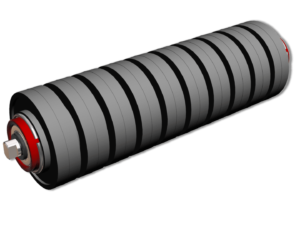

- Mounting possibilities for metal tubes, in diameters ranging from 60mm to 159mm and shafts from 17mm to 40mm.

- Electrowelded rolled steel tube, quality ST-37 according to DIN 17.200 standard.

- Round calibrated steel, F-212 and F-111 for diameters greater than 30mm.

- Shaft fastening, by means of external elastic circlips, type DIN 471 in different diameters.

- Mining bowl with or without flange, depending on the diameters. In any case, for fixing by electric welding. Made of deep drawing steel in RR ST-1403 quality with calibrated bearing seats.

- Precision bearing according to DIN 625 with one row of balls, according to the International Standard and ISO recommendation. Brand GPZ, WWB or similar.

- Metallic dust cover made of deep drawn steel or, according to shaft diameters, of polypropylene.

- This type of roller can be served in a natural, zinc-plated or painted finish.

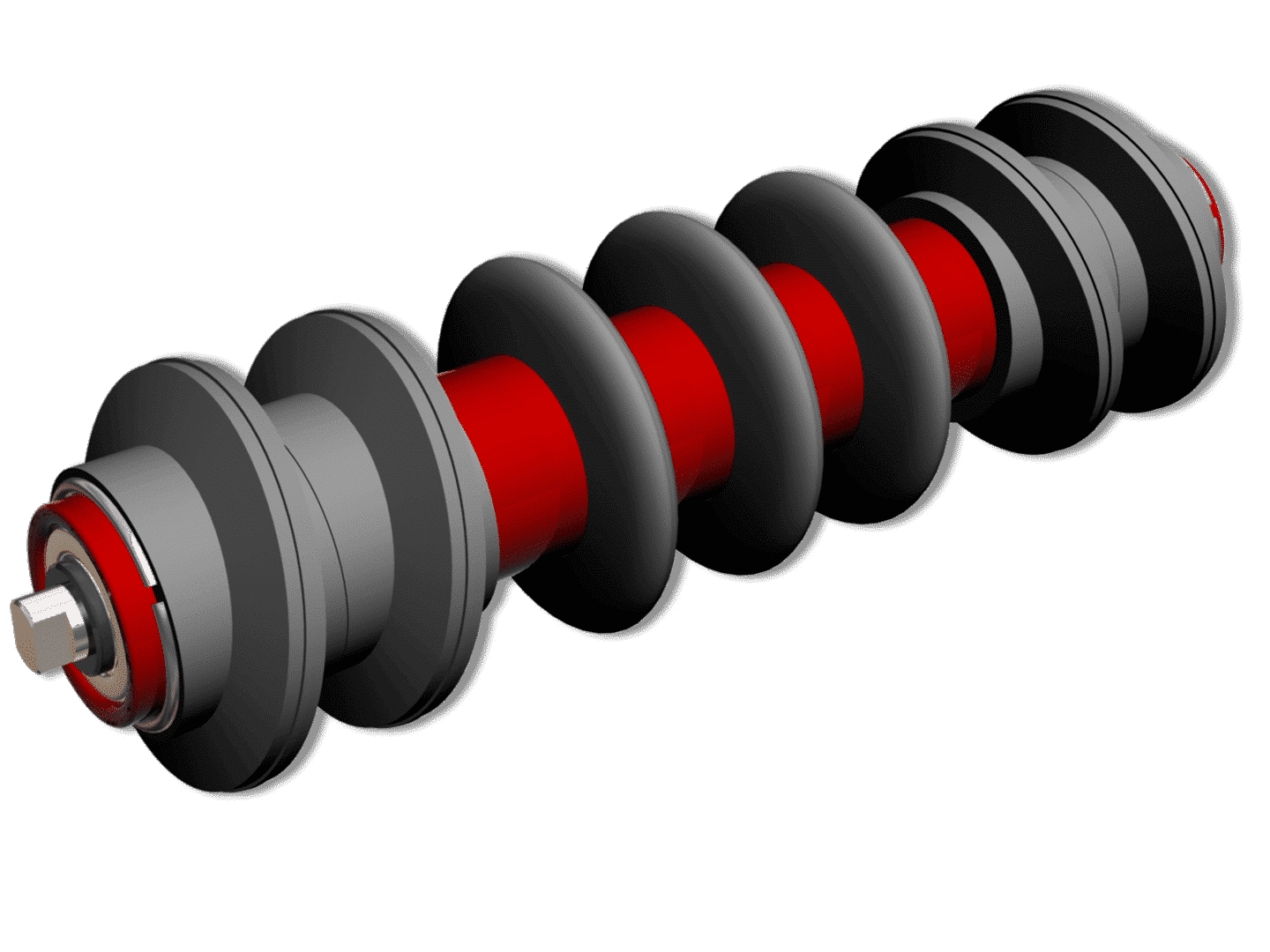

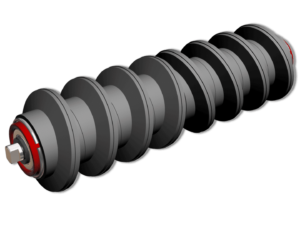

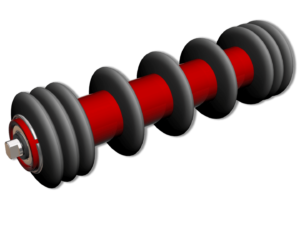

- As it is a mixed cleaning roller, it can be fitted with two types of rubber rings at the same time, … helical, oval or even shock-absorbing.

- Optimal sealing system for aggregate in general, by means of a labyrinth set of 4 or 5 pieces, depending on the diameter. Outer bushing, bottom adjustment and outer and inner labyrinths, made of polypropylene, with good mechanical properties and excellent resistance to shocks and blows. Use temperature, between 0 and + 80º.

- For cases of extreme humidity, sealing system for humid environments, by means of a three-piece ‘S’ protection set; two internal double lip silicone seals and an external metal sealing cap.

Download the Product PDF

Specifications Rubber Coating for Rollers

Specifications Mixed-Oval Symmetrical Damper

Specifications Mixed-Oval Asymmetric Shock Absorber

Specifications Central Cleaning Roller RSP