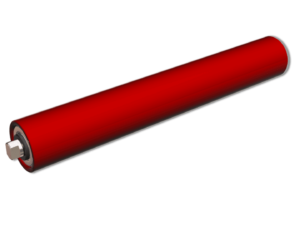

- Mounting possibilities for metal tubes, in diameters ranging from 60mm to 159mm and shafts from 17mm to 40mm.

- Electrowelded rolled steel tube, quality ST-37 according to DIN 17.200 standard.

- Round calibrated steel, F-212 and F-111 for diameters greater than 30mm.

- Mining bowl with or without flange, depending on the diameters. In any case, for fixing by electric welding. Made of deep drawing steel in RR ST-1403 quality with calibrated bearing seats.

- Precision bearing according to DIN 625 with one row of balls, according to the International Standard and ISO recommendation. Brand GPZ, WWB or similar.

- Shaft fastening, by means of external elastic circlips, type DIN 471 in different diameters.

- Optimal sealing system for aggregate in general, by means of a labyrinth set of 4 or 5 pieces, depending on the diameter. Outer bushing, bottom adjustment and outer and inner labyrinths, made of polypropylene, with good mechanical properties and excellent resistance to shocks and blows. Use temperature, between 0 and + 80º.

- Metallic dust cover made of deep drawn steel or, according to shaft diameters, of polypropylene.

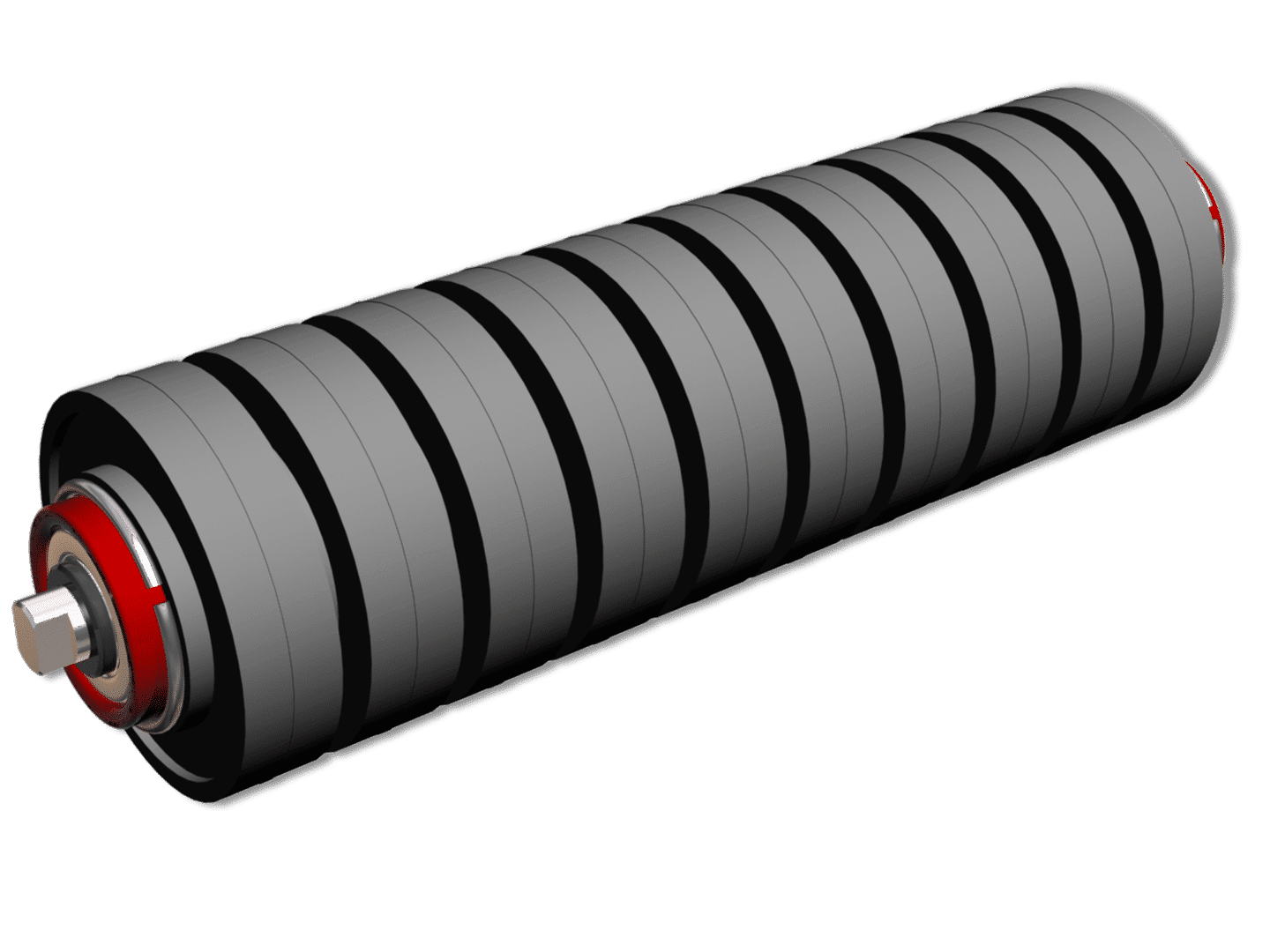

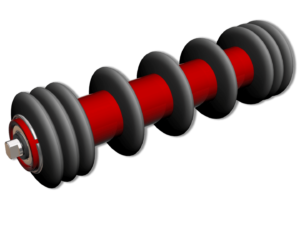

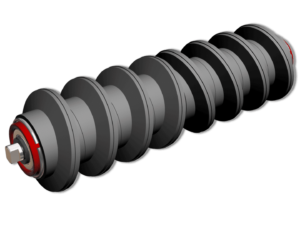

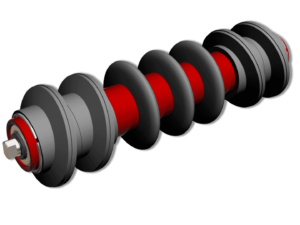

- Shock absorbing rubber bands, covering the surface of the roller totally or partially.

- This type of roller can be served in a natural, zinc-plated or painted finish.

- For cases of extreme humidity, sealing system for humid environments, by means of a three-piece ‘S’ protection set; two internal double lip silicone seals and an external metal sealing cap.

Download the Product PDF

Specifications RSP Roller Damper

Specifications Damper Roller

Specifications Cushion Roller Rubber Separate

Specifications Damper Roller Rubber Separate 2

Specifications Rubber coating for rollers